ABOUT US

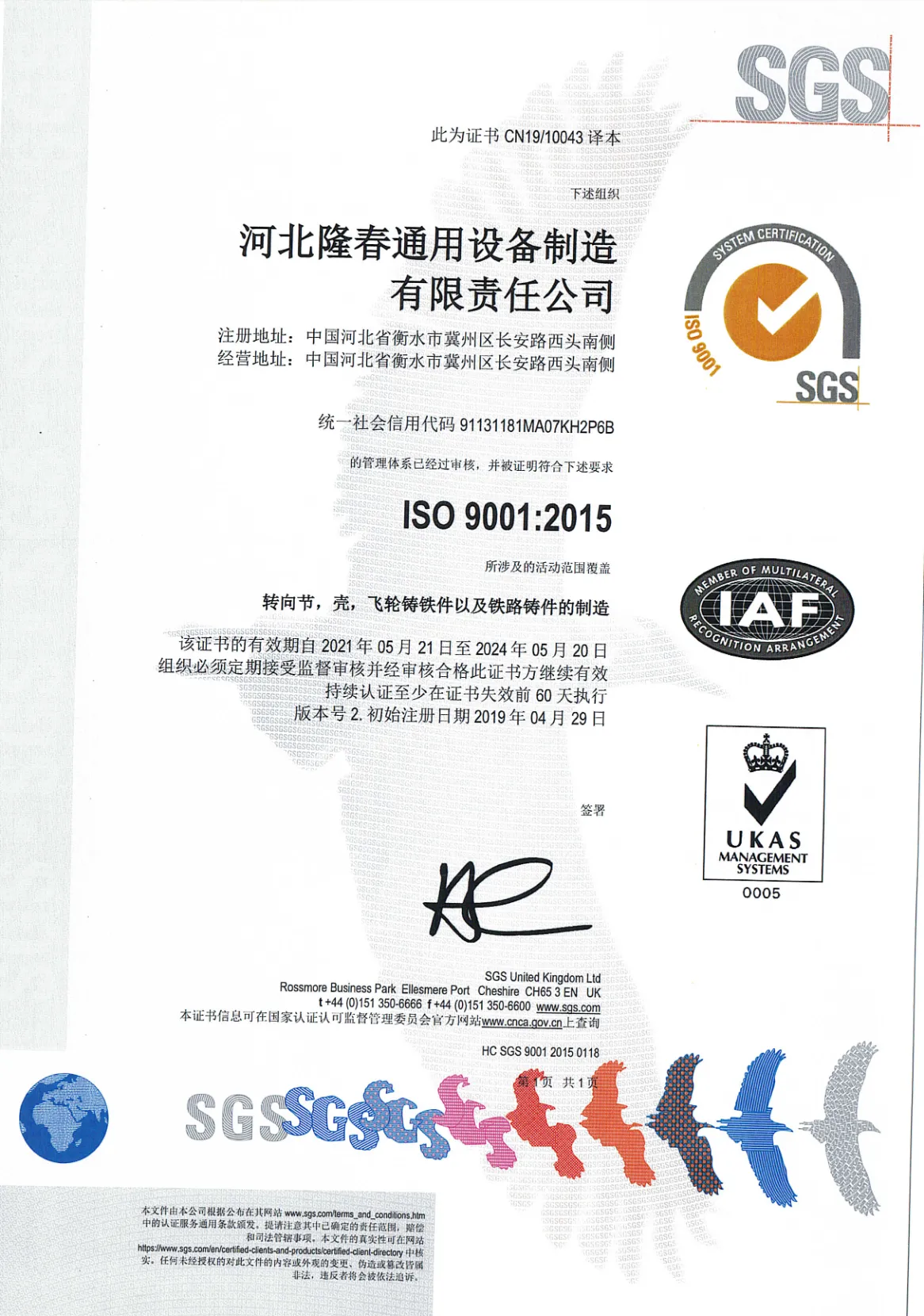

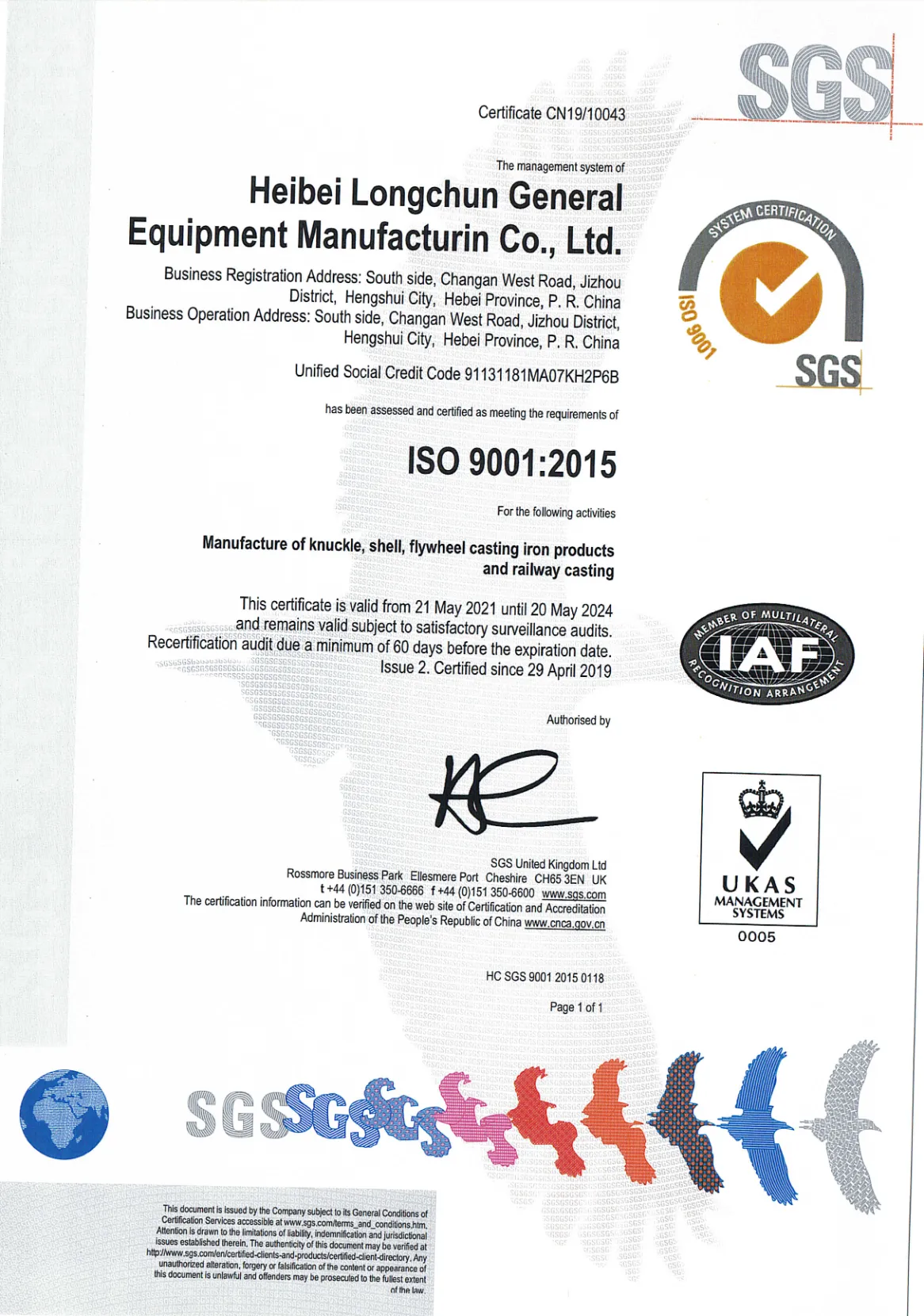

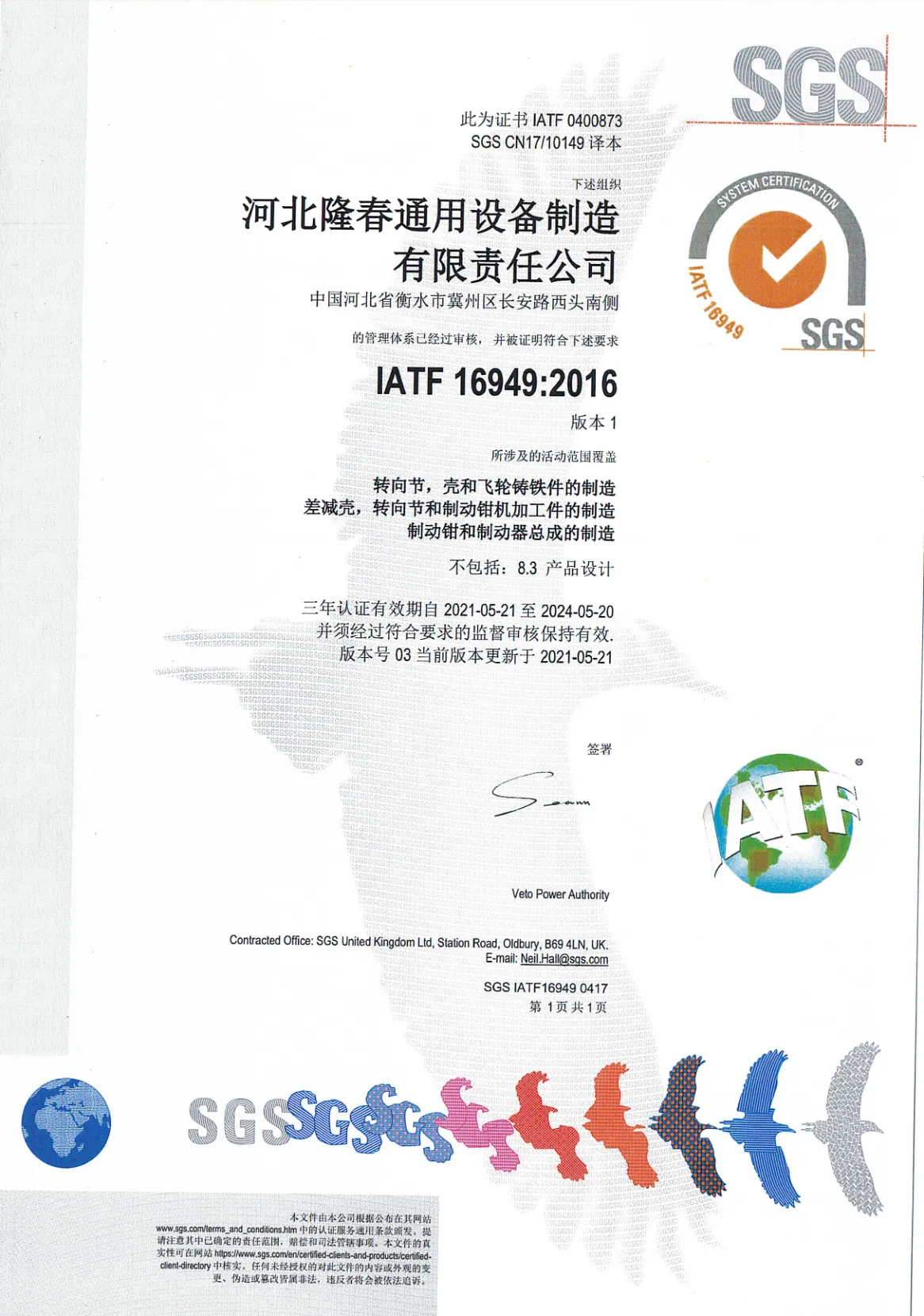

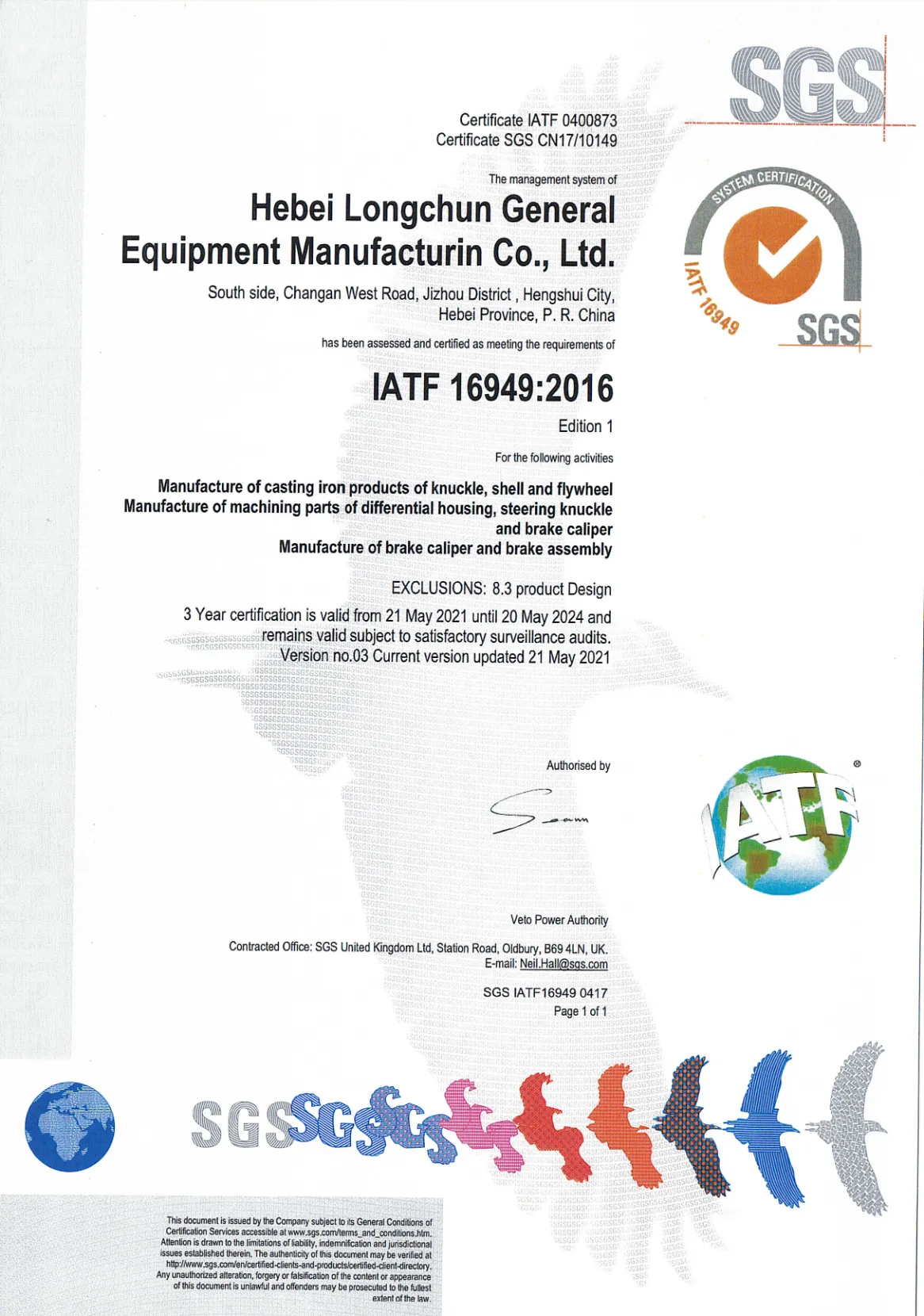

and the chairman unit of the Supervisory Board of the Hebei Casting and Forging Industry Association. The company has been rated as one of the top 100 comprehensive strength enterprises in China's foundry industry, the leading enterprise in China's foundry industry, and one of the 1,000 key backbone enterprises in China's foundry industry by the China Foundry Association for four consecutive terms; it has been rated as an AAA-level credit enterprise in China's foundry industry by the Ministry of Commerce and the State-owned Assets Supervision and Administration Commission of the State Council; a specialized and new enterprise; the company has been rated as a national environmental protection A-level enterprise, a green casting demonstration enterprise in Hebei Province, and a benchmark environmental protection enterprise in Hebei Province for five consecutive years. Hebei Longchun General Equipment Manufacturing Co., Ltd. has two branches, automotive safety parts casting and automotive parts processing and assembly. It integrates casting, processing, intelligent assembly and other advantages. The company takes the lead in implementing ISO/TS16949, ISO9001 quality system, and ISO14000 environmental management system.

Longchun automotive safety parts casting is equipped with two imported Japanese Shinto horizontal box-off automatic molding lines and matching French high-end sand processing lines, high-efficiency energy-saving medium-frequency electric furnaces using advanced American technology and other advanced equipment. The overall equipment has a high degree of automation and significant energy-saving and environmental protection effects. Longchun Automobile Safety Parts Processing and Assembly is equipped with world-class automobile reducer housing processing lines, differential housing processing lines, steering knuckle processing lines, brake caliper processing lines, brake automatic assembly lines and other most advanced production equipment in the same industry nationwide.

In terms of intelligent manufacturing, Hebei Longchun Company has developed a production data early warning system and MES management system, collected detailed production data of each device, established a big data model analysis system, realized data early warning, production optimization, and trend judgment, and provided important data support for production efficiency improvement, energy conservation and emission reduction. The system provides mobile office functions, and can view the factory's production status in real time through mobile phones, arrange production in real time, and solve the problem that managers cannot see data when they are on business trips, laying a solid foundation for intelligent manufacturing and networked collaborative manufacturing.

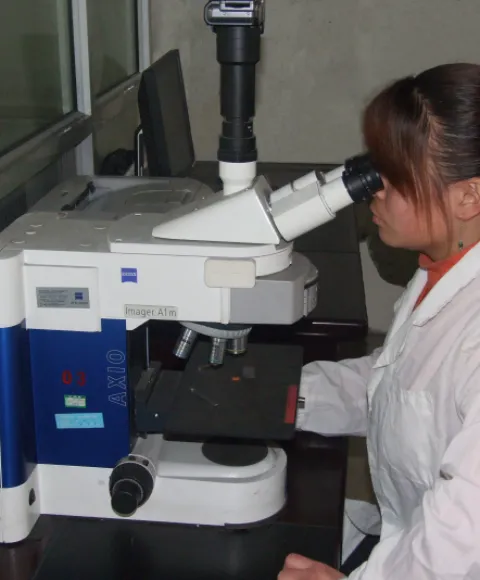

In terms of product inspection, the company has established Hebei Chunxin Quality Inspection Service Co., Ltd., which is certified by Hebei Province CMA. It has German spectrometers, German metallographic microscopes, X-ray online flaw detection lines, 3D scanners, ultrasonic flaw detectors, fluorescent magnetic particle flaw detectors, universal material testing machines, low-temperature impact testing machines, Brinell hardness testers, three-coordinate measuring machines, high and low temperature durability test benches, brake caliper comprehensive performance test benches, brake torsional fatigue strength test benches, salt spray test benches, inertia testing machines and other advanced testing equipment. It has the ability to inspect the performance and materials of national-level castings in all aspects, and has the ability and qualifications to provide inspections for third parties.

In terms of product research and development, the company has established the Automotive Safety Parts Casting Technology Research Institute, and has reached academic cooperation with many scientific research institutes and well-known universities to provide parts research and development for well-known domestic and foreign automobile manufacturers such as Great Wall, Changan, BMW, and Chrysler of the United States.

Hebei Longcun General Equipment Manufacturing Co., Ltd. has established and maintained its leading position in the market with its continuous innovation strength and stable product quality. Its products are installed on the review vehicles for the 60th anniversary of the National Day military parade and the salute tractors for the 70th anniversary of the victory of the Anti-Fascist War, becoming a model of high-quality safety parts. The company's automotive steering knuckles, flywheels, brake calipers, differential housings, brake discs, brakes and other automotive safety parts are distributed in Beijing, Tianjin, Hebei, Shanghai, Jiangsu, Zhejiang and other provinces and cities, becoming the designated supplier of well-known domestic automobile companies such as Mercedes-Benz, BMW, Chrysler, GM, Volkswagen, Great Wall, BAIC, Changan, BYD, and Chery. The company's high-speed railway, intercity light rail, subway special pads and other series of railway castings are sold well in major cities such as Beijing-Tianjin-Hebei, Shanghai, Changchun, and Shenyang, and exported to more than a dozen countries and regions such as the United States, Russia, and Italy.

In order to further expand the space for survival and development of the enterprise, the company extends from blank castings to parts and components, a complete industrial chain, develops in the direction of high-end casting, upgrades the enterprise level, increases product added value, strives to build a large-scale casting production base in northern China, and strives to create a new highlight of local economic growth. Hebei Longchun General Equipment Manufacturing Co., Ltd. is willing to work hand in hand with peer partners to create brilliant achievements!

and development, quality, and other aspects